Li.U Lab Model 3 Pressure Test

Succesful Pressure Test Of The Updated Lab Model V3 From The Three

Joint GREC Sustainable Groups Project at Linköping University

Background

As flagged by the Linköping University Workshop the GREC Lab Model V3

was not fully assembled in time for final the project presentation. The three

groups did a brave assembly after their presentation but before finishing

their term. Unfortunately time was running out again and they did not

achieve any results in their brief testings.

After the term nilsinside AB was allowed to borrow the Linköping Lab Model

during the summer season for debugging and updating in Varamon, Motala.

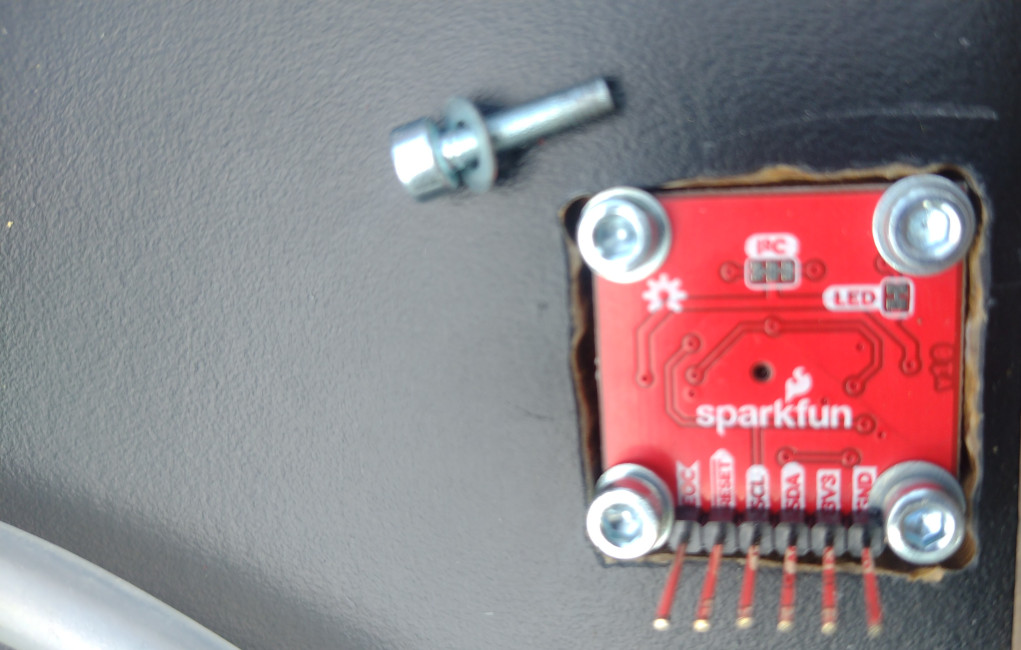

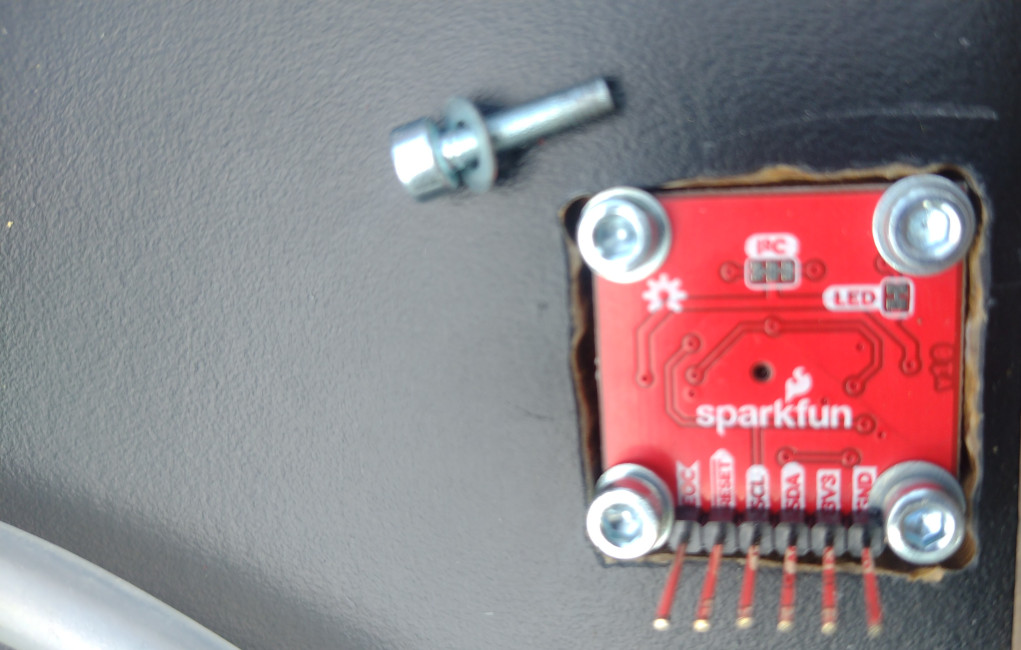

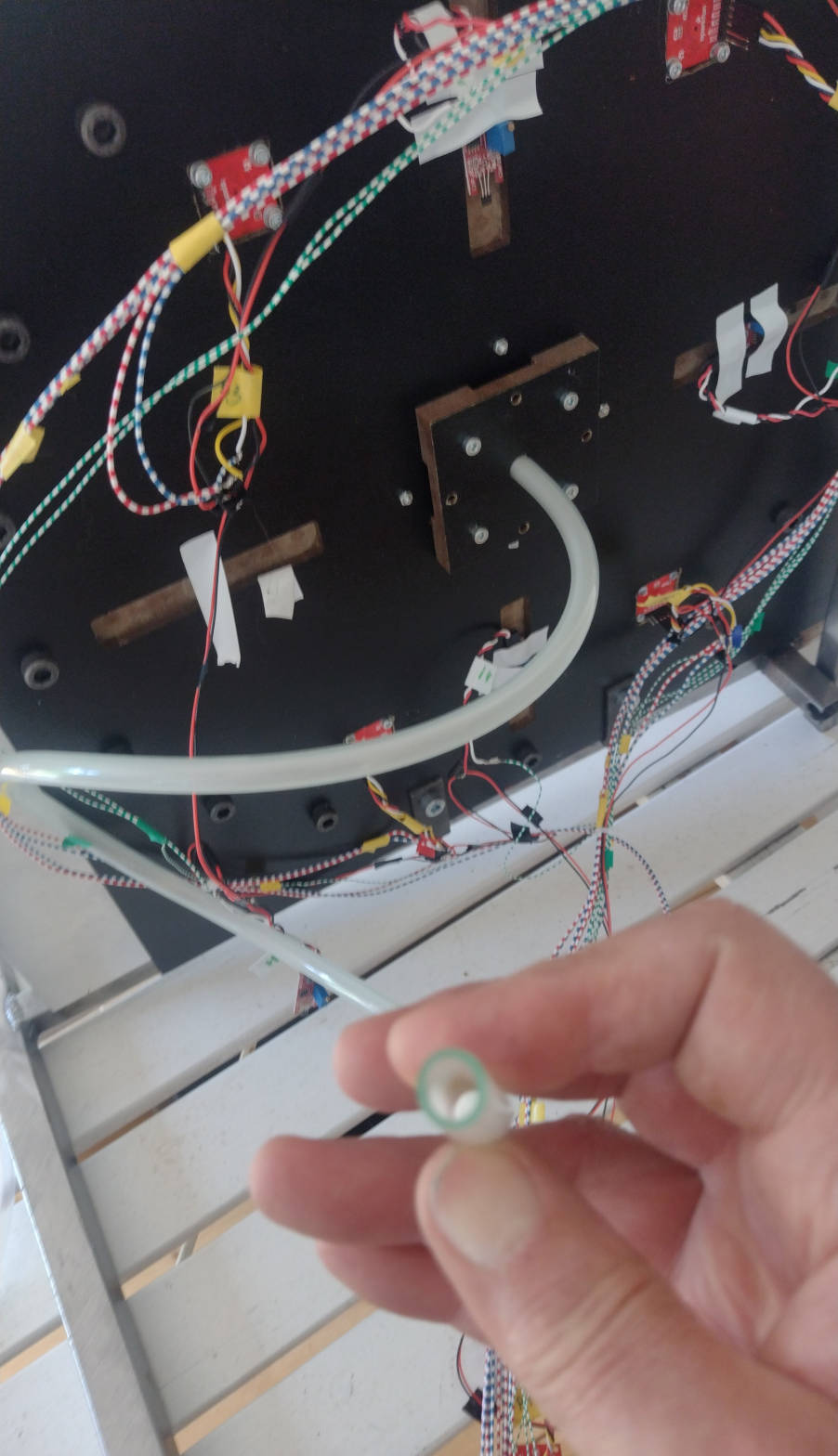

One of the four pressure sensors tested in the first GREC Lab Model V3 test at nilsinside AB

One of the four pressure sensors tested in the first GREC Lab Model V3 test at nilsinside AB

At nilsinside the the symptoms were analysed and systematic iterative work

was done to adjust and seal the GREC LabModel v3 during June and beginning

of July 2023. For every assembly it got a little bit better and the first

acceptable pressure test (this one) was conducted the 11th of July 2023 using

lungs and a plastic tubing.

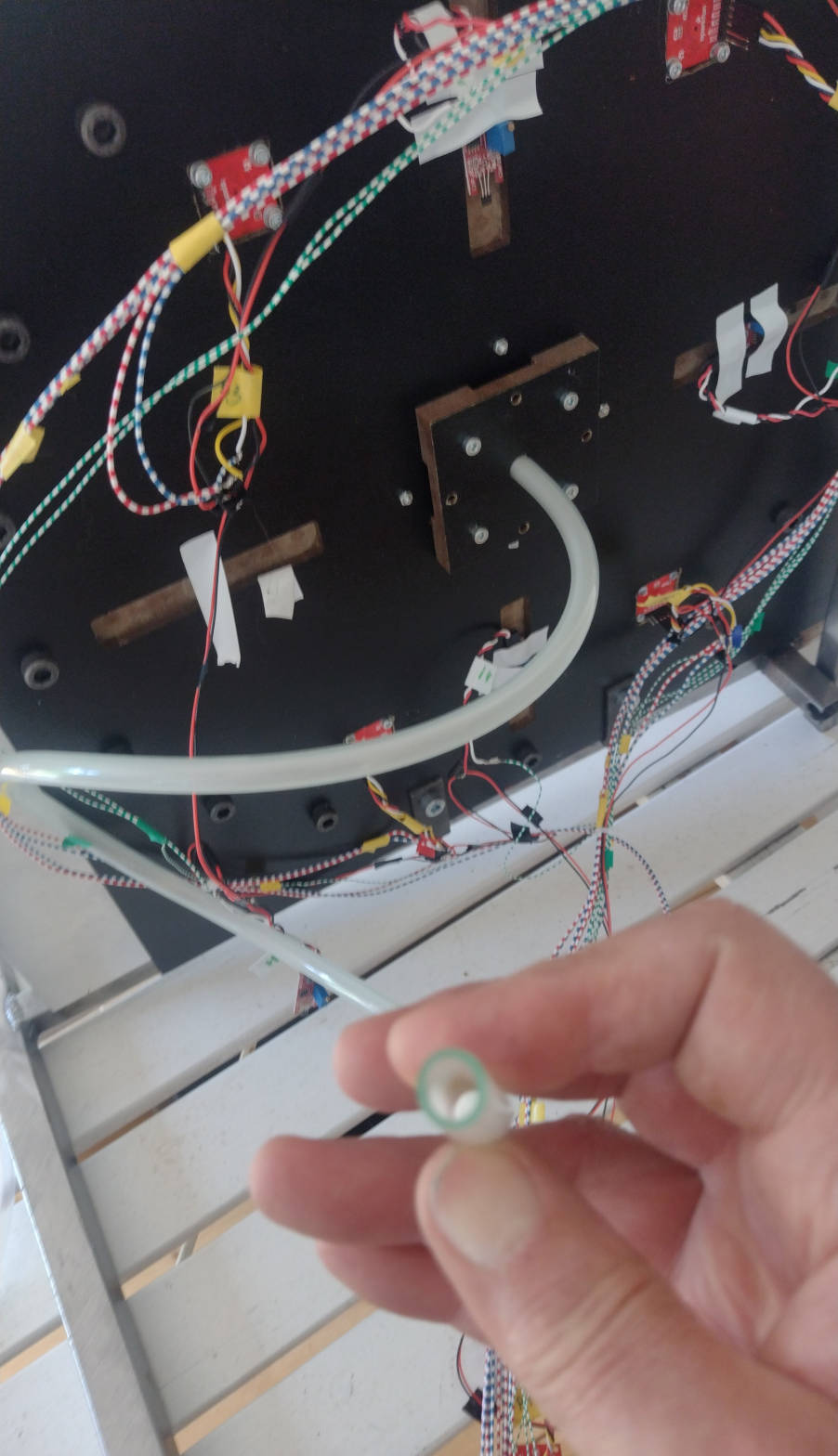

The Green Revolution Energy Converter (GREC) Lab Model V3 with

temporary plastic tubing. You may also locate the four pressure sensors.

The Green Revolution Energy Converter (GREC) Lab Model V3 with

temporary plastic tubing. You may also locate the four pressure sensors.

In this first short test the LabModel v3 was operated by the Mechatronics group

software "Kombinerad_kod.ino".

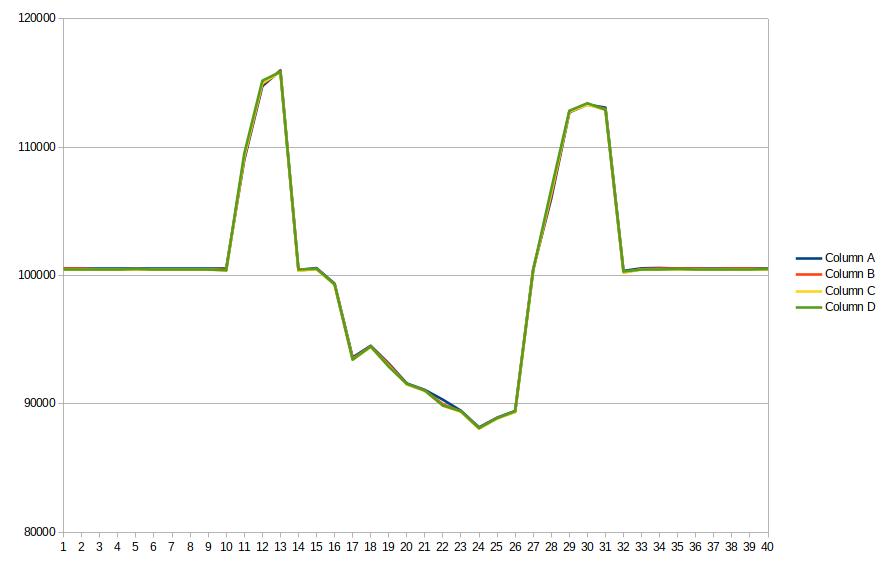

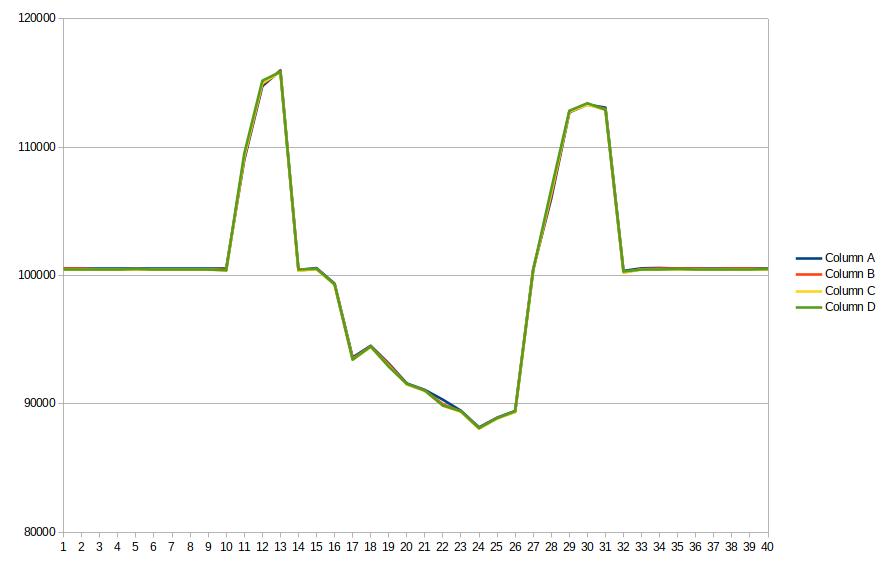

With a WGV revolution at 2 Hz (120 RPM) the software recorded the 4 pressure

sensors simultaneously in their 4 different

locations (Columns) WITHOUT any temperature difference between both of the heat

conducting sides. The four graphs follow each other so well that they almost

completely overlap. The Lab Model v3 finally appears to be without disturbing

friction and also fairly tight.

The Green Revolution Energy Converter (GREC) Lab Model V3 pressure/time test diagram with overlapping graphs

The Green Revolution Energy Converter (GREC) Lab Model V3 pressure/time test diagram with overlapping graphs

Ambient temperature: 19°C (292°K)

Temperature Gradient, ΔT = 0°C

Ambient pressure: 100 564 Pa

Maximum pressure in this test, P max: 115 977 Pa

Minimum pressure in this test, P min: 88 170 Pa

Pressure difference in this test, ΔP = 27 807 Pa (corresponds to an approximately

80°C heat gradient.)

Observations:

• Ambient pressure from time line 1 to 10

• Pressurization from 10 to 13 (by blowing)

• Relieving pressure 13 to 14

• Suppression from 15 to 17 and then blocking the tube

• More suppression from 18 to 24 and then blocking the tube again

• Relieving suppression from 26 to 27

• Pressurization from 27 to 30 and again blocking the tube

• Finaly relieving the pressure to ambient from 31 to 32

• Note: At the positions between 17 to 18 and from 24 to 26 and from 30 to 31 the

tube is completely closed so the linear coefficient shows a small leakage in

the GREC system boundary.

Hopefully the leak disappears when we tightly cover the R-S shaft passage areas.

• Note: The four different pressure graphs are momentarily separated in positions

between 12 - 13, and between 21 and 23 indicating a small variation between

the individual pressure sensor values. This may rather indicate a variation

in response time (which in turn may depend on sampling time in the I2C bus,

software, processor frequency, sensors etc.) than in a real pressure difference.

Next follow up will be a few tests with minor temperature gradients to confirm

if the graphs still overlaps. It might be that they separate proportional

to the revolving speed.

The Technology

In thermodynamic terms the GREC is a closed system with a moving boundary

where the GREC converts heat energy to kinetic energy. The GREC heats up

and cools down its internal large sliced WGV efficiently, fast and repetitively,

resulting in internal pressure changes.

These internal pressure changes are used by its moving boundary to generate

kinetic energy. You may think of the GREC as a revolving Carnot heat engine

controlled by computer logic. Please find the theoretical presentation of

the GREC on this link:

GREC Theory Presentation

The GREC is a new technological solution to tackle climate change. Spring 2023

there were three groups at Linköping University that thrived on the challenge

of a transition to fossil free energy systems. They constructed and built

the Lab Model v.3 as a step in the GREC climate positive project. Still leaking,

but this test turned out to be a significant proof of the GREC internal pressure

distribution. A real and repeatable physical proof. This Linköping University

Lab Model v3 is now ready for continuing research projects.

Please feel free to call or email:

Contact information at nilsinside AB

Nils Karlberg nils@nilsinside.com, tel +33 608 53 15 93, theory & technical questions

Sophia Karlberg sophia@nilsinside.com , strategy & admin questions

The GREC Project