Project:

SUSTAINABLE REVOLUTION PART 3 at Linköping University

During spring 2023 a new group of nine candidates plan to build Lab-Model v.3

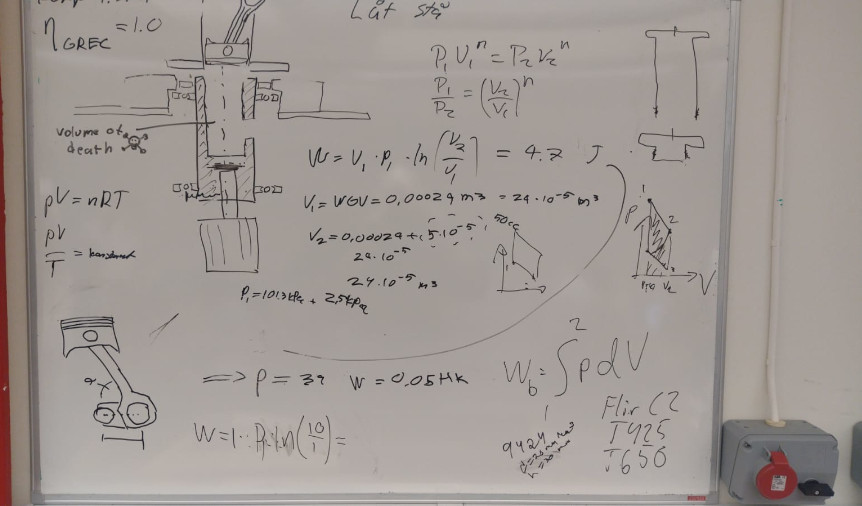

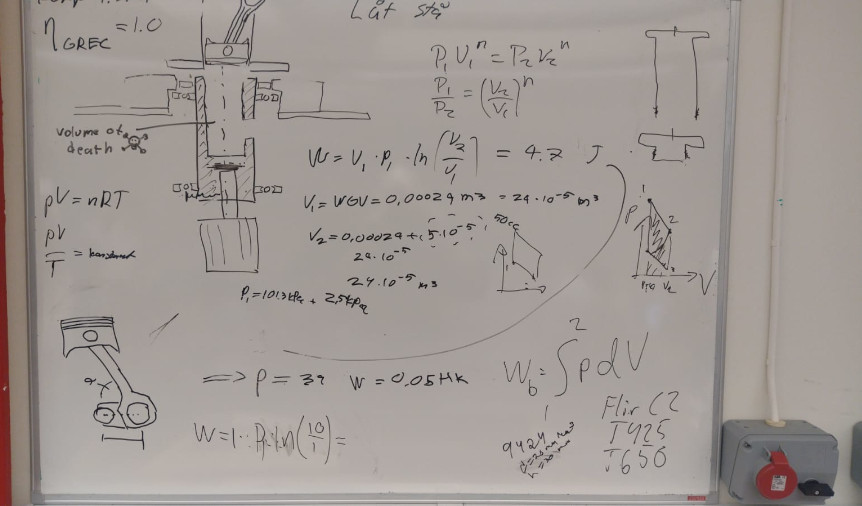

The Green Revolution Energy Converter (GREC) sustainable research at

Linköping University will build a physical model. This aims to answer if a

real revolving physical "Work Generating Volume" really will behave as predicted

in Li.U earlier theoretical research. Does theory and reality converge? Is

the GREC a future crucial climate-positive concept for an adjustable clean

energy production?

Background

The severe impacts of green house gas emissions on the global warming is today a fact. The

emissions can be coupled to several different sectors where heat and electricity production were

the sectors with the highest increase of CO2 emissions in 2021. The complexity of this turns out to

be greater than imagined since no bigger improvements has happened since the Paris

Agreement was signed by 196 UN countries in 2015, not even after COP27. Still new

technology solutions to inverstigate and luckily there are three new groups at Linköping University

in Sweden this spring that thrive on the challenge of a transition to a world not based on fossil fuels.

Investigating a new technology aiming to be applied both in the electricity production sector

and the transport sector.

The Project Goal

The goal is to build a simple tight model to deliver data in the simplest

way within the specified time frame. Time is important. The model does not

need to be optimal nor elegant but it has to be able to revolve its Work

Generating Volume (WGV) with electric control at different speeds while

logging pressure and average temperatures.

The work is divided into three parallel sub-projects/subject areas:

CONSTRUCTION group: Ida H, Andrei T and Simon S

• Building a closed thremodynamic system containing a revolving WGV between

convection surfaces. (CONSTRUCTION's group responsibility

is to get the Lab Model made within the timeframe)

Phase: Size, Dimensions & Material

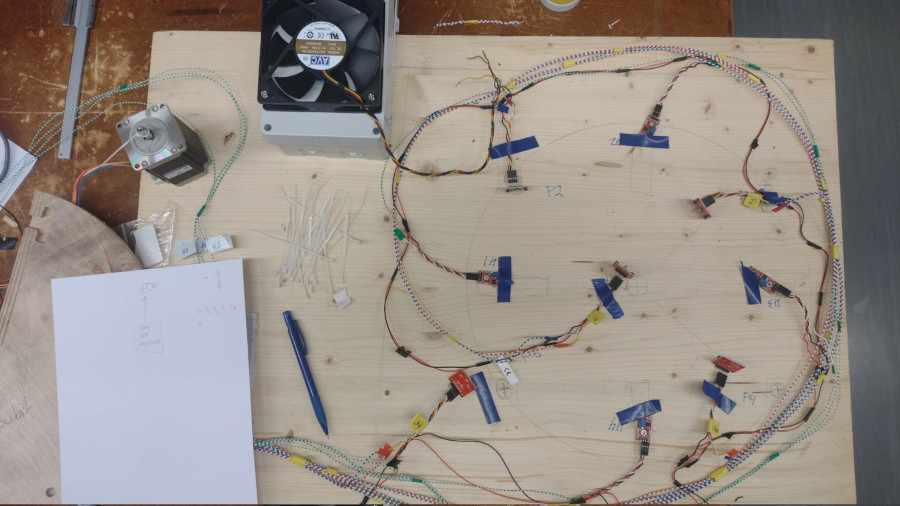

THERMODYNAMIC group: Vidar J, Jakob R and Johan Å

• Set up measurable heat transport to and from the model. Preferably with

internal sensors for average temperature in convection surfaces and WGV

from the MECHATRONICS group.

(THERMODYNAMIC's group will focus on setting up and connecting the hot and the

cold side for calculations at good operating and measurement conditions)

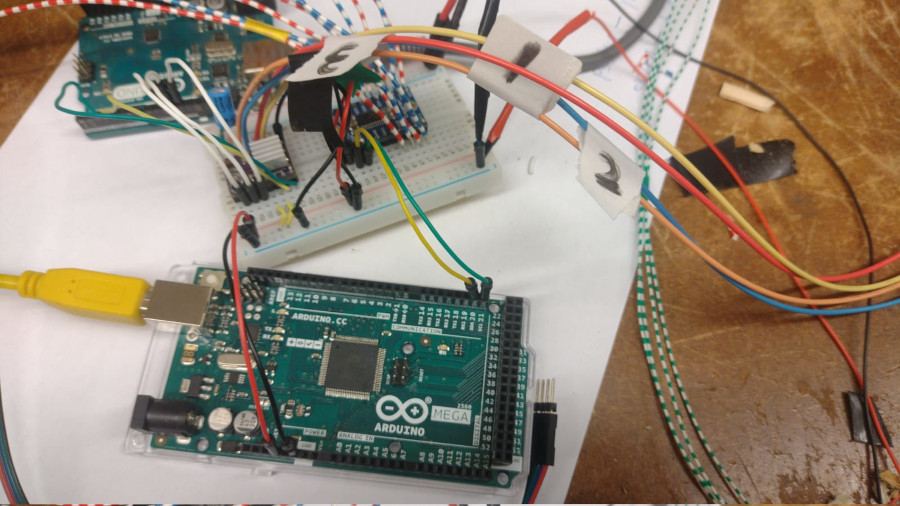

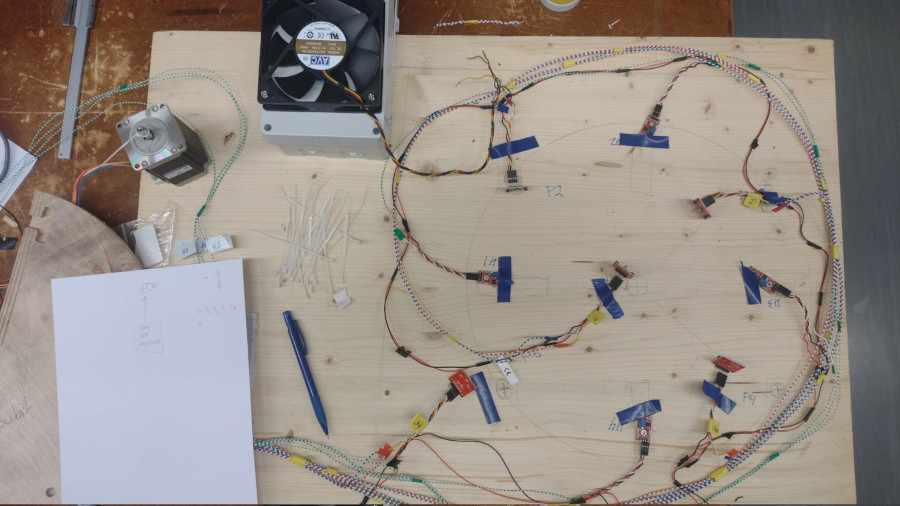

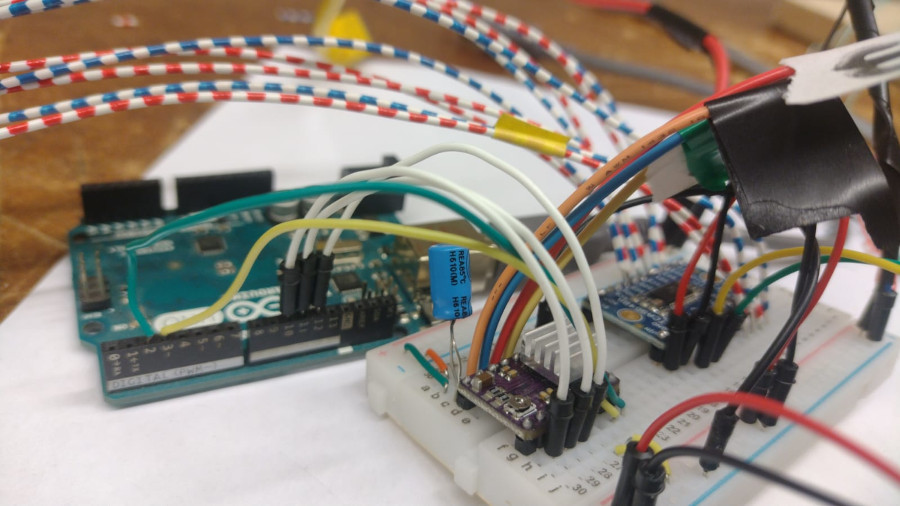

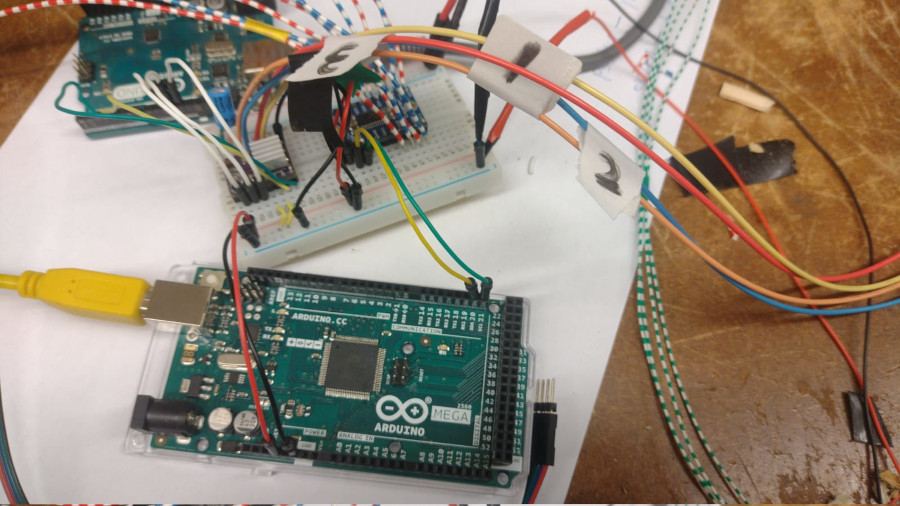

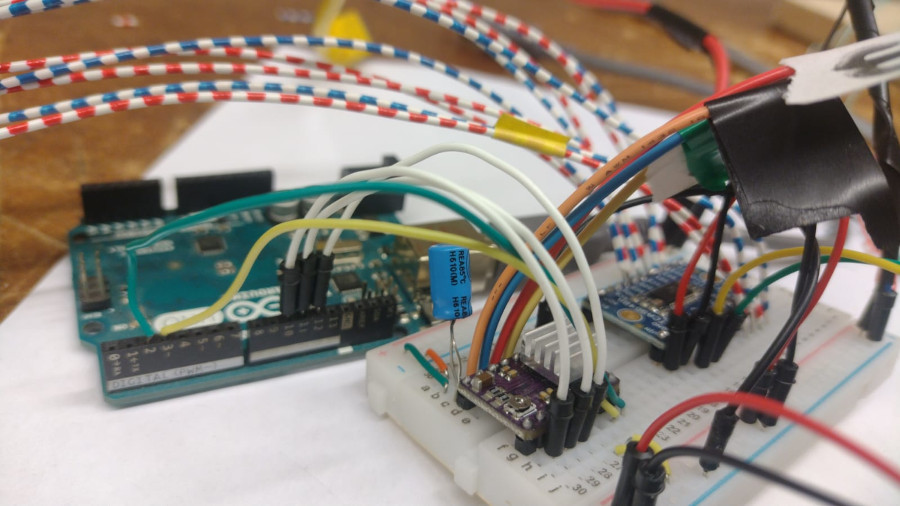

MECHATRONIC group: Oskar B, Lisa V and Max H

• They will program and setup electronics to measure and logg pressure pulses

and deliver to the result to THERMODYNAMIC group (who will calculate the volume

change work and calculate real time energy output)

The Lab Model version 3

The new LabModel v3, under construction, differs somewhat from the old LabModel v2.

Budget, time and the very important goal that it should be TIGHT with MINIMAL FRICTION

between the Revolving-Shutter and the large internal fin surfaces for heat convection

and the adiabatic fin surfaces (future "moving boundary").

• In order to ensure the experimental runs it has a significantly

MORE POWERFUL STEPPER MOTOR.

• Diameter and Volume

- The diameter is around 38 cm (versus 58 on LabModel v2)

- Revolving Shutter in the new LabModel v3 has greater height

(thickness approx. 8 mm instead of 6mm if I remember correctly)

- The dead volume between the Revolving Shutter and the surfaces inside

in volume is aimed to be significantly smaller in the new LabModel v3

than in Lab Model v2.

• LabModel v3 is only one layer (LabModel v2 has two)

- The shaft thus has only ONE Revolving Shutter

• System limit

- the Revolving Shutter shaft crosses the system boundary

with sealed ball bearings (LabModel v2 had encapsulated

shaft ends)

• Sensors and Control

- The new Lab Model 3 has an integrated electric heat source

which enables a measurable energy delivery and has a fewer

number of built-in sensors.

The GREC Technology

In thermodynamic terms the GREC is a closed system with a

moving boundary where the GREC converts heat energy to kinetic energy.

The GREC heats up and cools down its internal large sliced WGV efficiently,

fast and repetitively, resulting in internal pressure changes.

These internal pressure changes are used by its moving boundary to generate

kinetic energy. You may think of the GREC as a revolving Carnot heat engine

controlled by computer logics. Please find the theoretical presentation of

the GREC on this link:

GREC Theory Presentation

The GREC is a new technological solution to tackle climate change and luckily

three groups at Linköping University this spring thrived on the challenge of

a transition to fossil free energy systems. The construction and building of

the GREC Lab Model v.3 is an important step in a climate positive project that

will feed several successful research projects over time...

Please feel free to call or email:

Contact information at nilsinside AB

Nils Karlberg nils@nilsinside.com, tel +33 608 53 15 93, theory & technical questions

Sophia Karlberg sophia@nilsinside.com , strategy & admin questions

The GREC Project